Physical Vapor Deposition

Description

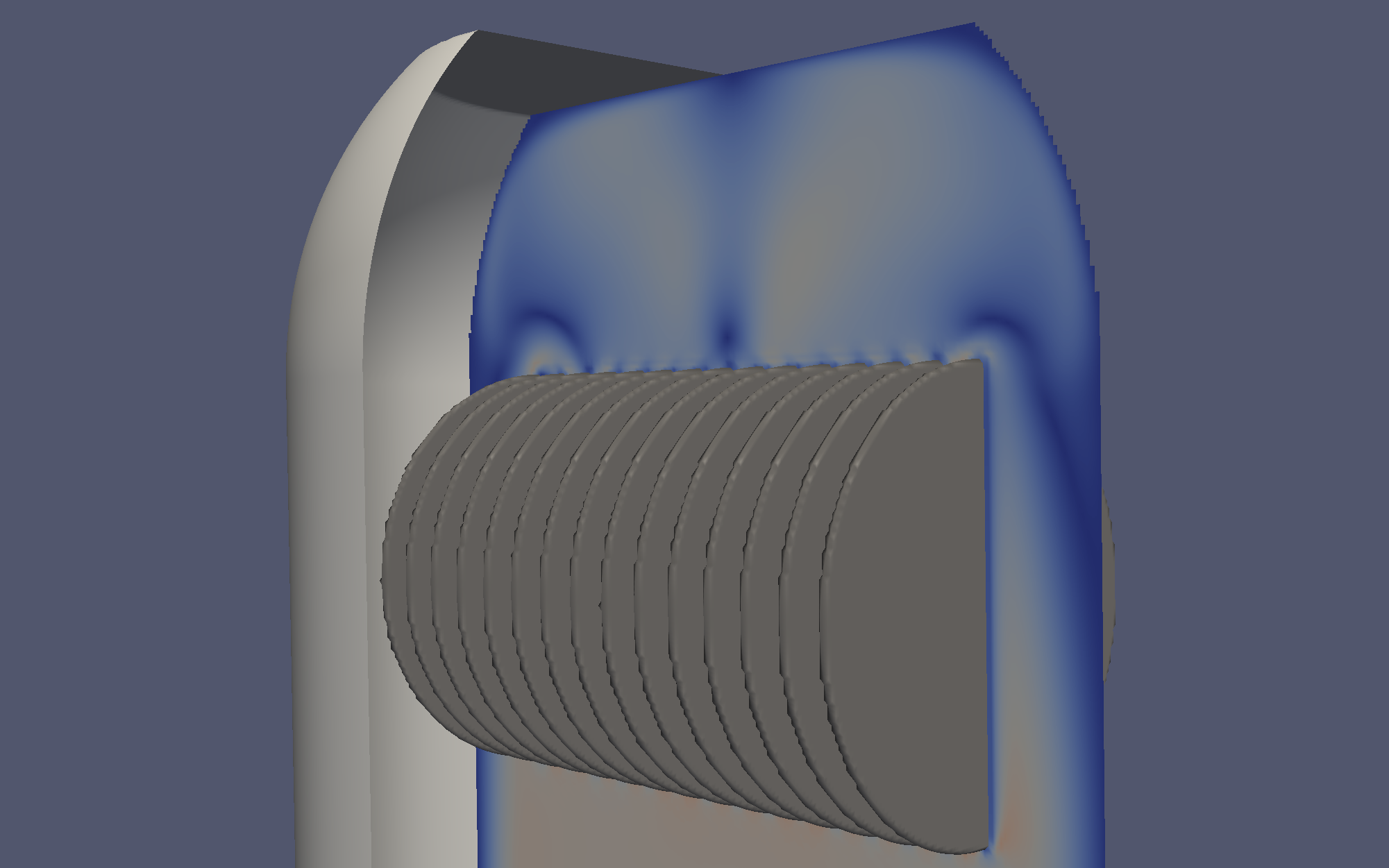

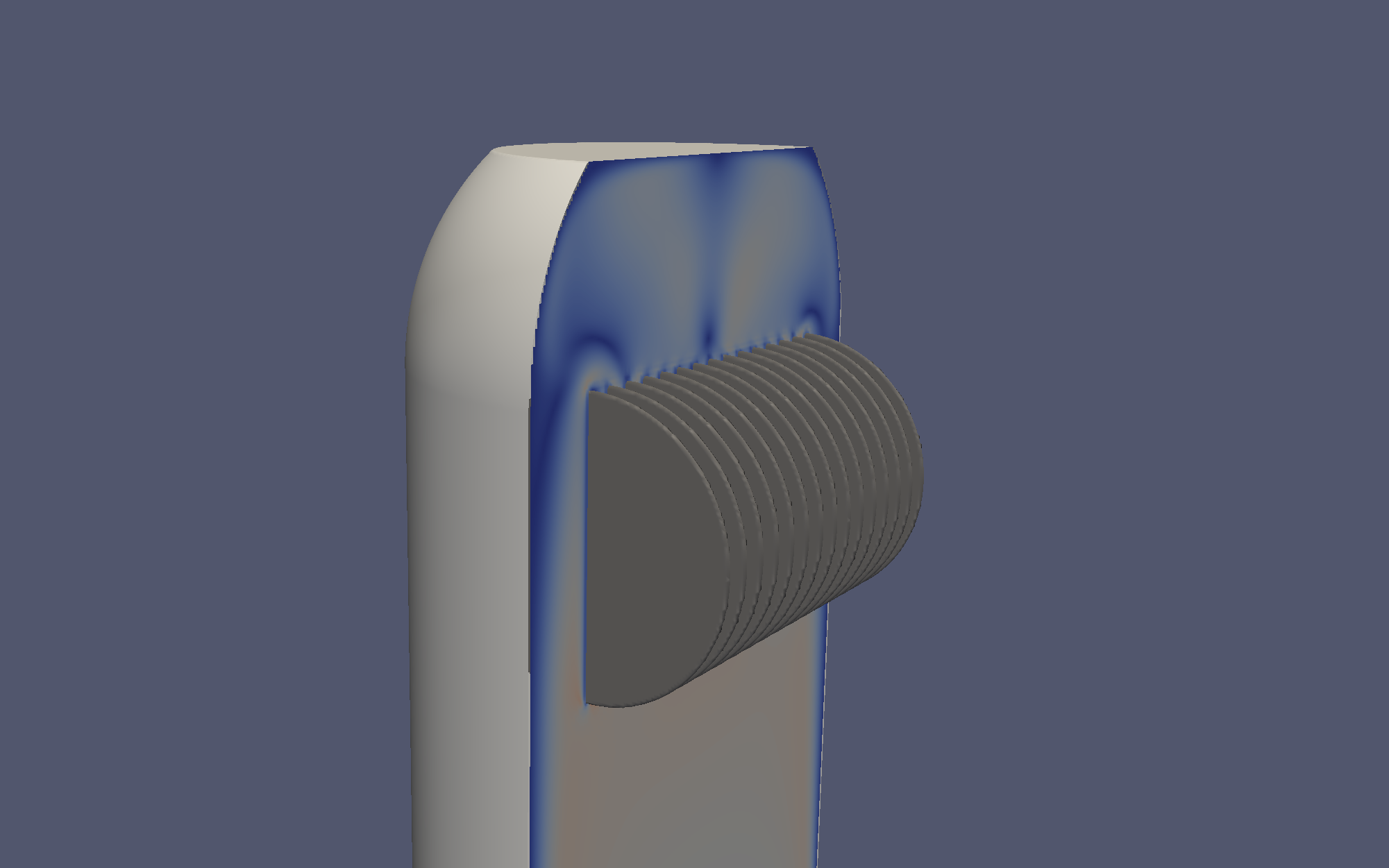

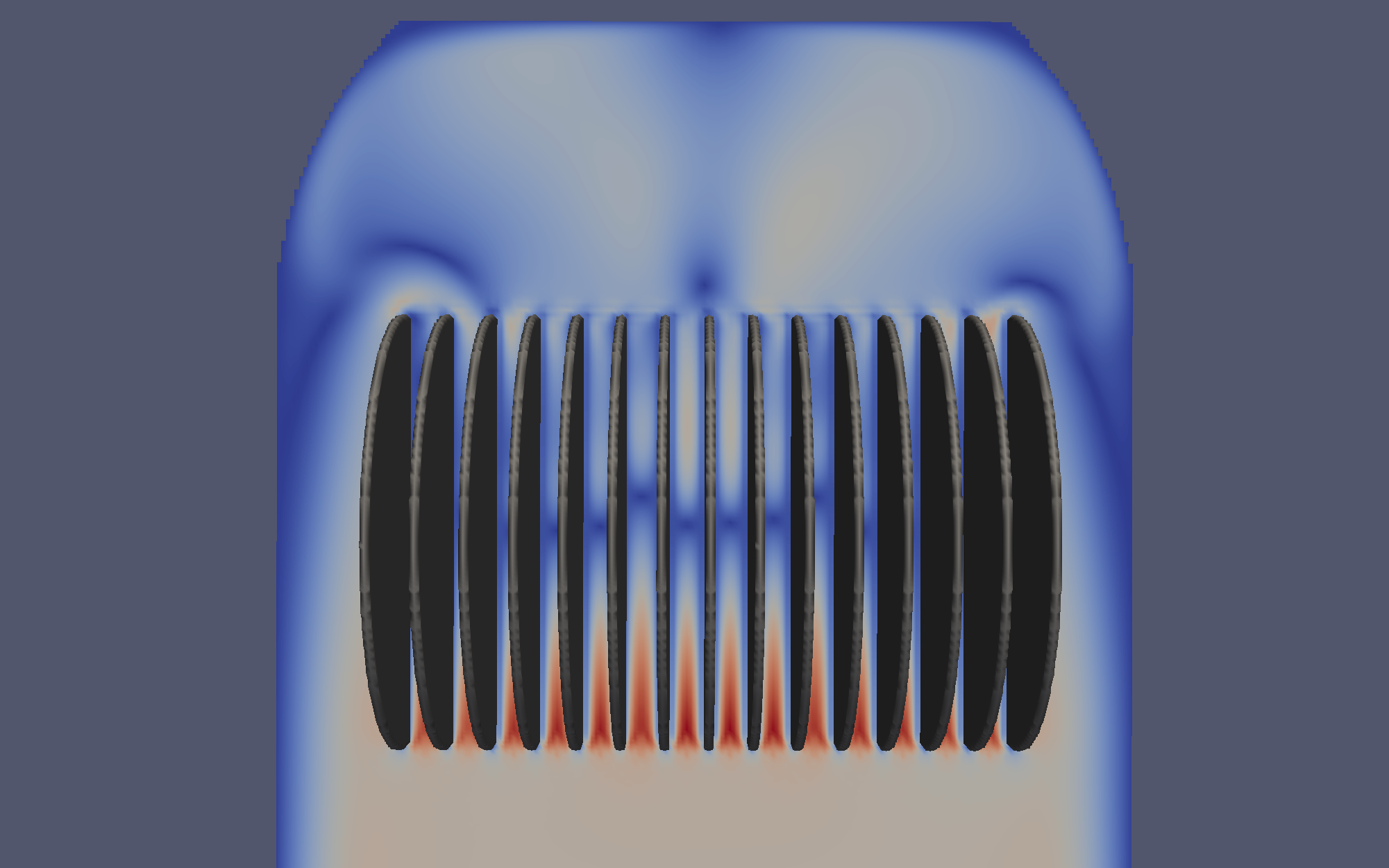

Simulation of circular saw discs coating procedure employing Physical Vapor Deposition (PVD) method. This metallization technique is used in a wide variety of other applications such as semiconductor wafers, photovoltaic cells, thin-film batteries, optical coatings, etc.. Present modeling can be utilized to optimize different output parameters of PVD: layer thickness uniformity, energetic efficiency, process duration, costs and productivity.

Screenshots

Platform used

- CPU: AMD FX(tm)-6300 Six-Core Processor 3.5GHz

- RAM: 8Gb

- GPU: Sapphire AMD Radeon HD 7950 3GB GDDR5 Boost OC

- OS: 64-bit Debian GNU/Linux

Numerical setup

- Domain size: 204 x 204 x 373

- Number of points: 15’522’768

- Resolution: 0.36 cm

- Physical size: 72 x 72 x 133 cm³

- Number of iterations: 30’000

- Physical time: 3600 s

Results

- Computation time: 1018 s